Oil dry fractionation is a process to separate vegetable oils into two fractions, Olein and Stearin, by the crystallization properties of oils and without the addition of chemicals or solvents. The same plant can also be used to produce super olein and palm mid fraction of varying cloud point and melting point.

Oil dry fractionation, also known as crystallization from the melt, is fractional crystallization in its simplest form. The widespread use of the three oil modification processes—hydrogenation, interesterification and fractionation has extended the range of applications of the triglyceride oils. These processes principally achieve the purpose of modifying the melting properties of oils and fats in order to improve their functional properties in specific applications, but the processes are also used to improve the stability of the oils and fats thus processed.

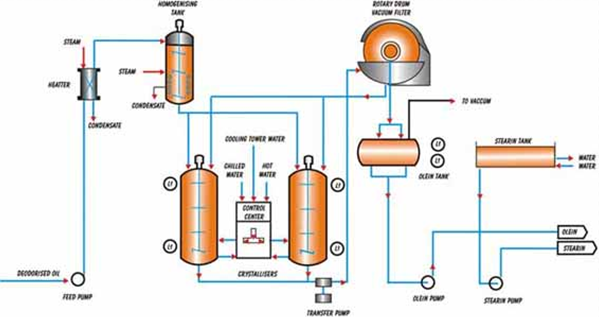

The process contains:

1. Preheating the feed stock to give a homogenous mass with nil solids.

2. Crystallisation under preset controlled conditions of temperature & agitation to form stable, uniform sized filterable crystals.

3. Filtering on membrane press filter (or Rotary Drum Vacuum filter) to separate the solid/liquid fractions.

Primary Advantages of Oil Dry Fractionation

1. Combines all operations, and monitors from a fully automated centralized control station.

2. Easy to operate, requires minimum supervision. Good flexibility. Wide range of process applications possible.

3. Feedstock can be crude, semi refined or fully refined palm oil.

4. Suitable for both single and double fractionation.

5. Minimum operating costs:

–Low utility consumption

–Low maintenance cost

–No oil losses

–No pollution problem

6. Product quality

–Good crystallization repeatability, yielding consistent product quality

–High Olein yields

–Low Olein cloud point, with improved cold stability; Could point as low as 2°C with iodine value of 65.0 can be obtained.