Nowadays, biomass pellets are more and more popular. Except for application in the industrial boilers, they are also widely used in home heating and cooking. As clean, green and renewable energy, biomass pellets are very economical. Their ash can be used as fertilizer.

To make high-quality biomass pellets, our small biomass pellet plant is exactly what you need. Our small biomass pellet plant makes good pellets from a variety of biomass materials, like: sawdust, rice husks, wood shavings, wood chips, straw, hay, peanut shell, bamboo sawdust, bagasse and alfalfa, etc.

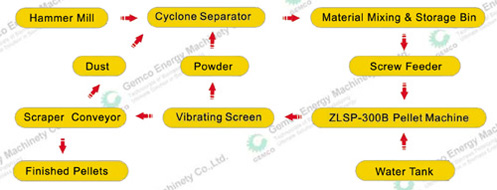

Our small biomass pellet plant is actually a small complete pellet production line that includes all the necessary equipment used in biomass pellet production. It is mainly composed of hammer mill, cyclone separator, material mixing & storage bin, screw feeder, ZLSP-300B R-type pellet machine, water tank, vibrating screen, bucket conveyor, foundation frame and electric cabinet.

Our small biomass pellet plant is actually a small complete pellet production line that includes all the necessary equipment used in biomass pellet production. It is mainly composed of hammer mill, cyclone separator, material mixing & storage bin, screw feeder, ZLSP-300B R-type pellet machine, water tank, vibrating screen, bucket conveyor, foundation frame and electric cabinet.

Detailed information of small mobile pellet plant main parts:

| MPL300 small mobile pellet plant equipment list | ||||

|---|---|---|---|---|

| No. | Equipment Name | Features | Power (kw) | |

| Ⅰ Crushing system | ||||

| 1 | Hammer Mill | It’s with 15 hammer blades, by changing the different position of the blades, it’s suitable for crushing woody or biomass or forage material with size less than 20 mm (diameter), the size of the output crushed material can reach diameter 3-5mm. |  Hammer Mill Hammer Mill |

|

| 2 | Pneumatic Conveying Unit | This unit includes one 2.2kw air blower, wind pipeline and cyclone separator. It will transport the crushed material into bin for mixing and storage. It’s connected with vibrating screen and bucket conveyor with semitransparent soft pipes to cool the pellets, and collect the powder and dust. | ||

| ⅡMaterial Mixing, Storage & Conveying Section | ||||

| 3 | Material Mixing, Storage Bin | It’s with 1m3 volume, its shell is made of 2.5 mm steel plate. There are two portholes on both sides for monitoring and observation. Four paddle type mixers is driven by one 0.75KW motor. The highest material level for this bin is at 800mm from the bottom. |  Storage Bin Storage Bin |

|

| 4 | Screw conveyor | The input port for mixed material is at the bottom of the bin. It’s 112mm in diameter, 1023 mm long. It is to feed the mixed material into the pellet mill, and is driven by frequency conversion speed controlled motor, 0.18 KW, frequency conversion range is 30~60 Hz. | ||

| Ⅲ Pelletizing Section | ||||

| 5 | Pellet Machine | This ZLSP-300B R-type pellet machine makes 0.4 ton wood pellets per hour by using pure sawdust. The water adding system is connected and available to adjust the moisture content of the mixed material. We can make 6, 8 mm pellets (diam.). |  ZLSP300B R-type pellet machine ZLSP300B R-type pellet machine |

|

| 6 | Water Tank | This tank can carry 100 L water. The water pump is at 24V, capacity : 5L/min, water discharge pressure: 8.5kg, flow meter capacity: 0.2-2GPM | ||

| Ⅳ Sieving & Pellet Conveying Section | ||||

| 7 | Vibrating sieve | 3.5*3.5mm Mesh, with 0.37KW power. The size of the mesh can be changed according to your requirements. One φ45mm soft pipes is connect to collect the powder and dust. |  Vibrating Sieve Vibrating Sieve |

|

| 8 | Scraper conveyor | It’s driven by chain, the scraper size is at 145mm. The size for single section is 2436*437*484 mm. The length and height of this conveyor can be extended by adding and connecting one extra section. There are five positioning joints at the end of the conveyor, you can adjust the height and angle of the conveyor easily. Two φ100mm soft pipes is connect to cool the pellets. | ||

| V Auxiliary Equipments | ||||

| 9 | Steel structureABS | With Anti-skidding steel floor |  Schnerider Electric components Schnerider Electric components |

|

| 10 | MCC control centre | The electronic components in this system are made by Schneider Electric with international standard. The manual operation control system is adopted. You can easy control this plant according to your demands. Two frequency converters are used to control the speed of the Screw Conveyer and Scraper Conveyor. The control cabinet is with dust prevention. The emergency stop and smart power lock is adopted. | ||

| Total power for above all | 41.25kw | |||

Our small biomass pellet plant have many advantages, like: small size, compact structure, low power consumption, low noise, high output rate, easy operation, convenient maintenance, and long service life.

Technical parameter of our small biomass pellet plant:

| Model | MPL300 |

|---|---|

| Capacity | 250-350kg/h (or 350-450kg/h for ZLSP-400B pellet machine) |

| Pellet diameter | 6-12mm |

| Power | 41.25kw |

| Size | 3500*1960*3500mm |

The raw material goes via the following processes:

The finished pellets made by our small biomass pellet plant are have high density and smooth and delicate surface. They have high density and can offer lasting energy.

Apart from small biomass pellet plant, we provide timely delivery, skilled technical guidance, and excellent after-sales services!